categories

recent posts

What is anodic oxidation? Why anodic oxidation?

What is anodic oxidation?

The anodic oxidation of aluminum is an electrolytic oxidation process in which the surfaces of aluminum and aluminum alloys are usually converted into an oxide film, which is protective, decorative and some other functional properties.

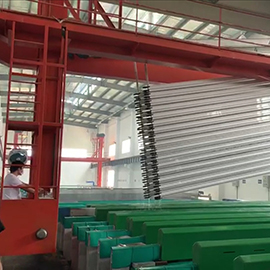

The general process of anodizing aluminum products is as follows:

Aluminum workpiece ---Upper hanging gear---degreasing---water scrubbing---Alkali corrosion---water scrubbing---glaring---water scrubbing---anodic oxidation---water scrubbing---deionized water washing ---Dyeing or electrolytic coloring---water scrubbing---seal---water scrubbing---Lower hanging tool

Why do you want anodizing?

In order to overcome the defects of surface hardness and wear resistance of aluminum alloy, expand the application range and prolong the service life, surface treatment technology has become an indispensable part in the use of aluminum alloy, and anodizing technology is the most widely used and the most successful at present.

Anodizing of aluminium

In the acid electrolyte, the aluminum is used as the anode, and the material protecting technology for producing the oxide film on the surface of the aluminum through the electrolysis is adopted. The anode of aluminum is oxidized with a plurality of electrolyte, but is basically formulated with sulfuric acid, chromic acid, oxalic acid or boric acid as the main component. Most commonly used in the form of a sulfuric acid group. The power supply may be DC, AC, or AC. The voltage is between 5 and 25 volts and the temperature is lower than 25 DEG C.

In the process of electrolysis, the anion of oxygen interacts with aluminum to produce oxide film. When the film is first formed, it is not fine enough and has a certain resistance, so that the negative oxygen ions in the electrolyte can still reach the aluminum surface and continue to form an oxide film. With the increase of film thickness, the resistance increases and the electrolytic electrorheology decreases, while the outer oxide film in contact with the electrolyte dissolves at the same time. When the rate of oxide formation on the aluminum surface is gradually balanced with the rate of chemical dissolution, this oxide film can reach the maximum thickness under this electrolytic parameter. The structure of the anodized film of aluminum is different from that of other conversion films. The dense layer of 0.01 μ 0.1 μ m is near the metal part of the matrix, and the honeycomb layer is composed of many hollow hexagonal columns. the total thickness of the anodized film is 2 μ 100 μ m. The anodized films produced by various electrolytes are of different colors, some of which are colored as a whole and are mostly used in the construction industry. Some of them can be colored by dye or deposited in the hollow part of the hexagonal column by means of hydrolysis and double decomposition, thus increasing the aesthetic feeling.

Finally, it needs to be closed and dried. The corrosion resistance of aluminum with anodized aluminum film is sometimes better than that of aluminum treated with chromate. In addition to widely used in construction industry and daily hardware products, this aluminum is also used in aircraft, cars and civil ships. Using low temperature, weak solubility electrolyte and high voltage (100 × 150 volts), a hard anodized film for engineering can be formed, which can be used for mechanical parts and hydraulic components in contact with fiber, paper and rubber. The parts with very low friction coefficient can be obtained by filling the hexagonal cylinder cavity of ordinary anodized aluminum layer with polytetrafluoroethylene (PTFE).

copyright © 2026 Aluprofilescnc.all rights reserved.

friendly links :

Wall mount sensor faucet Color coated aluminum coil/sheet factory Industry Tools Manufacturer Medical Health Electrical Control Panel Box Fittings And Railing Systems pressure gauges Aluminum door and window Mu Metal Core Manufacturer guangyaaluminium Aluminum Window Supplier Custom Injection Molding