categories

recent posts

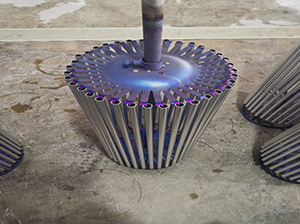

PRODUCT INTRODUCTION ANODIZED AFTER CUTTING CNC MACHINING

1. The parts subject to anodizing can be respectively mounted on general or special hangers according to their shape and size.

2. Before installation and hanging, the hanger must go through alkali corrosion or filing to remove the old oxide film on the surface of the hanger.

3. During installation and hanging, the parts shall be firmly clamped, but shall not be pinched, especially the parts with thread machined.

4. Install and hang the large skin with medium-sized hanger, and tighten the bolts to prevent falling off when swinging up and down in the solution.

5. For box shaped parts, tube shaped parts and machined parts with blind holes, the holes and mouths of the parts shall be upward, so that the gas generated during anodizing can be freely removed, otherwise, air bags will be formed, so that local surfaces are free of oxide film.

6. Aluminum rivets, washers and other small parts can be installed in rivet baskets for anodizing. Before loading the baskets, the rivets shall be corroded and polished, and the baskets shall be loaded after cleaning. During oxidation, in order to increase the conductive contact and reduce the amount of rework, some aluminum chips (about 10% - 20% of the rivet volume) can be added properly when the rivet is installed in the basket, and mixed with the rivet and washer. After filling, add the gland and fix it with aluminum nuts. When it is fixed, shake it to hear if there is any loose sound. If there is a big noise, it should be tightened again, but not too tight.

7. Parts made of the same material shall be installed on a hanger, and one hanger is not allowed to install parts made of two materials.

8. For anodized parts, if fixture seal is not allowed on partial or whole surface, process allowance shall be reserved for card mounting.

9. A certain interval shall be kept between each fixture to avoid the collision between parts. A certain interval should be kept between the parts and the cathode, and the surrounding of the cathode can be checked with an aluminum bar before power on.

copyright © 2026 Aluprofilescnc.all rights reserved.

friendly links :

Wall mount sensor faucet Color coated aluminum coil/sheet factory Industry Tools Manufacturer Medical Health Electrical Control Panel Box Fittings And Railing Systems pressure gauges Aluminum door and window Mu Metal Core Manufacturer guangyaaluminium Aluminum Window Supplier Custom Injection Molding