categories

new products

CNC Machining Aluminium Precision Service Parts CNC machining aluminium precision service parts is high and the machining quality is stable more

Types of led aluminum extrusion profiles Aluminum alloy has good extrusion characteristics, especially suitable for extrusion processing, which can be machined by a variety of extrusion processes and die structures more

Leave a message

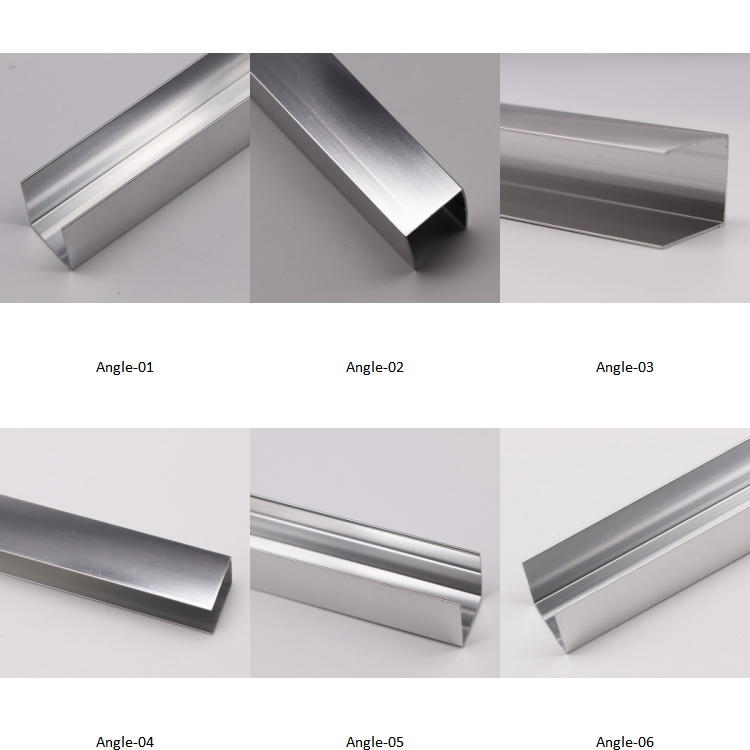

Aluminum alloy extrusions, various frame types, tubes can be customized wholesale, to undertake a variety of ODM / OEM

item no.:

XHG-3J0005lead time:

1-30daysproduct orgin:

Fujian Chinabrand:

XHGshipping port:

Xiamenpayment:

L/C,T/T,or otherscolor:

silverySilver white aluminum door frame extrusion

Product Description

|

Product Name |

Silver white aluminum door frame extrusion |

|

Material |

Alloy 6063/6061/6005/6060 T5/T6 etc. As clients require |

|

Color |

Red,black,blue,white,green,Orange,Silver,customized |

|

Standard |

ISO9001,SGS |

|

Surface treatment |

Sandblasting,anodized,electrolysis,polishing,customized |

|

OEM/ODM |

Available |

|

Delivery date |

1-30 days,according the quantity of your requirement |

|

Used |

Our products have a wide use, such as Equipment, Electronic, Amplifier, Machinery, Furniture,Bathroom and so on |

Feature of Silver white aluminum door frame extrusion

1.In the extrusion process, the extruded metal can obtain a stronger and uniform triaxial compression stress state than rolling forging in the deformation zone, which can give full play to the plasticity of the machined metal itselft

2. Extrusion molding can not only produce rod, pipe, shape and wire products with simple section shape, but also produce profiles and pipes with complex section shape.

3. Extrusion molding flexibility, only need to replace die and other extrusion tools, can be produced on a equipment with different shapes, specifications and varieties of products, the operation of replacing extrusion die is simple and fast, time-saving and efficient

4. The process is short, the production is convenient, the whole structure with larger area than hot die forging or forming rolling can be obtained by one extrusion, the investment of equipment is less, the cost of die is low, and the economic benefit is high.

Company profile

FAQ

Q: What do I need for offering a quote ?

A: Please offer us 2D or 3D drawings (with material, dimension, tolerance, surface treatment and other technical requirement etc.) ,quantity, application or samples. Then we will quote the best price within 24h.

Q: What is your MOQ?

A: MOQ depends on our client's needs, besides,we welcome trial order before mass-production.

Q: What is the production cycle?

A: It varies a lot depending on product dimension,technical requirements and quantity. We always try to meet customers' requirement by adjusting our workshop schedule.

Q: What kind of payment terms do you accept?

A.: T/T, L/C, Escrow, paypal, western union, moneygram etc.

Q: Is it possible to know how is my product going on without visiting your company?

A: We will offer a detailed products schedule and send weekly reports with digital pictures and videos which show the machining progress.

Q: If you make poor quality goods,will you refund our fund?

A: We make products according to drawings or samples strictly until them reach your 100% satisfaction.And actually we wont take a chance to do poor quality products.We are proud of keeping the spirit of good quality.

For more questions, please send inquiry or e-mail or call us ! Thanks !

previous :

Advanced material 7075 aluminum extruded rectangular profilenext :

U shape aluminum frame alloy extrusion profilesIf you are interested in our products and want to know more details,please leave a message here,we will reply you as soon as we can.

copyright © 2026 Aluprofilescnc.all rights reserved.

friendly links :

Wall mount sensor faucet Color coated aluminum coil/sheet factory Industry Tools Manufacturer Medical Health Electrical Control Panel Box Fittings And Railing Systems pressure gauges Aluminum door and window Mu Metal Core Manufacturer guangyaaluminium Aluminum Window Supplier Custom Injection Molding